Type:195, 201, 202, 304, 410, 430

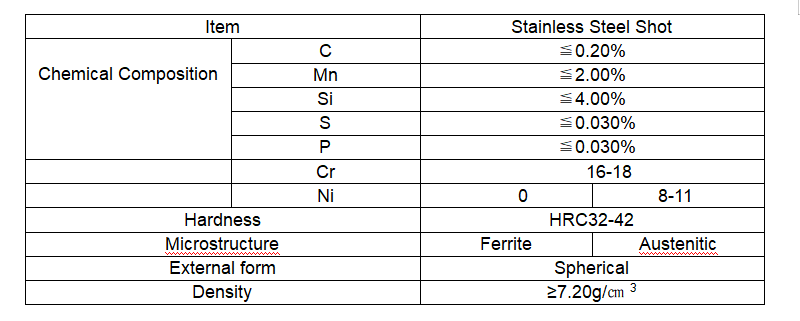

Technical indicators of stainless steel shot

,

Stainless steel shot production implementation standards

We strictly follow American SAE standards and Japanese JIS standards to produce stainless steel wire components to produce stainless steel shot for sand blasting and shot blasting.

Application scope of stainless steel shot

1. Stainless steel shot cleaning: shot blasting, shot blasting, non-ferrous aluminum alloy, copper alloy, magnesium alloy, zinc alloy die casting cleaning, stainless steel casting shot blasting,

stainless steel forgings shot blasting, forging shot blasting, casting sand cleaning, stainless steel plate clean up,

2. Stainless steel material cleaning, stainless steel plate cleaning, surface deburring and smoothing processing of colored parts can improve the fatigue resistance and corrosion resistance

of the workpiece and cover up surface defects of castings, making the surface of the product whiter and brighter.

3. Stainless steel shot rust removal: shot blasting, shot blasting, casting rust removal, forging rust removal, steel plate rust removal, forging scale removal, steel rust removal, H-beam rust

removal, steel structure rust removal.

4. Stainless steel shot peening: stainless steel parts shot peened, heat treated parts shot peened.

5. Stainless steel shot peening: shot peening of non-ferrous aluminum, copper, magnesium and zinc die castings, shot peening of stainless steel.

Application scope of stainless steel shot

Stainless steel shot is an abrasive used in shot blasting machines, shot blasting equipment, shot blasting machines, shot blasting equipment, sand blasting machines, sand blasting equipment, steel pretreatment production lines, steel plate pretreatment production lines, and steel structure pretreatment production lines.