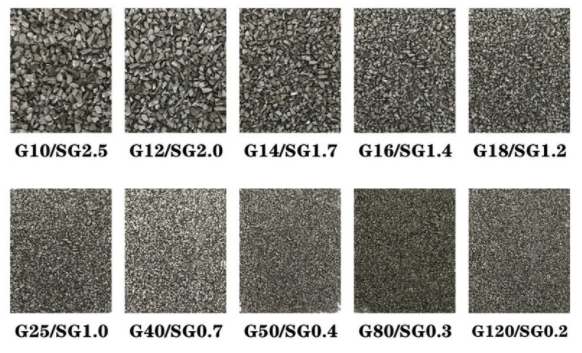

Type:G-10、G-12、G-14、G-16、G-18、G-25、G-40、G-50、G-80、G-120

Technical indicators of bearing steel grit

Project | Qualification | Test method |

Chemical Composition | C | 0.65~1.2% | P | ≦0.025% | ISO 9556:1989 |

Si | 0.15~0.6% | Cr | 0.2~0.4% | ISO 439:1982 |

Mn | 0.45~0.85% | Mo | 0.1~0.15% | ISO 629:1982 |

S | ≦0.025% | Ni | / | ISO4935:1989 |

| ISO 10714:1992 |

Microstructure | Homogeneous tempered sostenite |

Density | ≥7.4g/㎝3 |

Appearance | Flat shape,much angular,sharp angular |

Hardness | HV:600~700(HRC:55~60) HV:700~810(HRC:60~65) |

Performance feature

| The being steel has chromium,molybdenum rare elements,it has good stability inside structure,bearing steel grit has high stable performance,high wear resistance,its working life is 2.5 times as long as high-carbon steel shot and low carbon steel shot. |

Product description

The raw material of bearing steel grit is bearing steel. Bearing steel has high and uniform hardness and high cycle times, as well as high elasticity.

The uniformity of the chemical composition of the bearing steel, the content and distribution of non-metallic inclusions,

The requirements such as the distribution of carbides are very strict, and it is one of the most demanding steel types in all steel production.

Bearing steel grit is made from forged bearing steel that is directly quenched and then crushed. There is no smelting process in the manufacturing

process and there are no casting defects. It is an energy-saving and pollution-free product.

Compared with cast steel sand, bearing steel sand can not only be used as a cleaning product, but also can be used as an abrasive for manufactur-

ing molds to polish and grind bearings and other workpieces.

Bearing steel grit contains the precious metal chromium. Through a unique production process, it has an excellent metallographic structure, full

product particles, uniform hardness, and high number of cycles, which can effectively increase the recycling rate and thereby reduce the consum-

ption rate of abrasives.

Bearing steel sand is the safe choice for sandblasting and rust removal in the industry.

Precision quality: Use electric arc furnace smelting to effectively reduce the harmful elements sulfur and phosphorus in the product, effectively control the product deformity rate,

and the Airbus rate.

Strict quality control: It is less than 4% lower than the industry standard. The centrifugal pelletization method effectively controls the molding quality, reduces the deformed empty

shell rate of the product, and increases the number of product cycles.

Quenching technology: Secondary quenching technology changes the internal metallographic structure of the product, making it more compact, increasing the impact toughness

of the product, and increasing the number of product cycles.

Bearing steel grit uses

This product is made of forged bearing steel, which is crushed after heat treatment and then screened by heat treatment. This type of steel sand is special steel sand for cutting granite stone.

It has the characteristics of good edge angle, uniform particle size, and good wear resistance. It has been proven by many stone manufacturers for many years that it can cut stone

faster and the stone sawing board surface will be smoother.