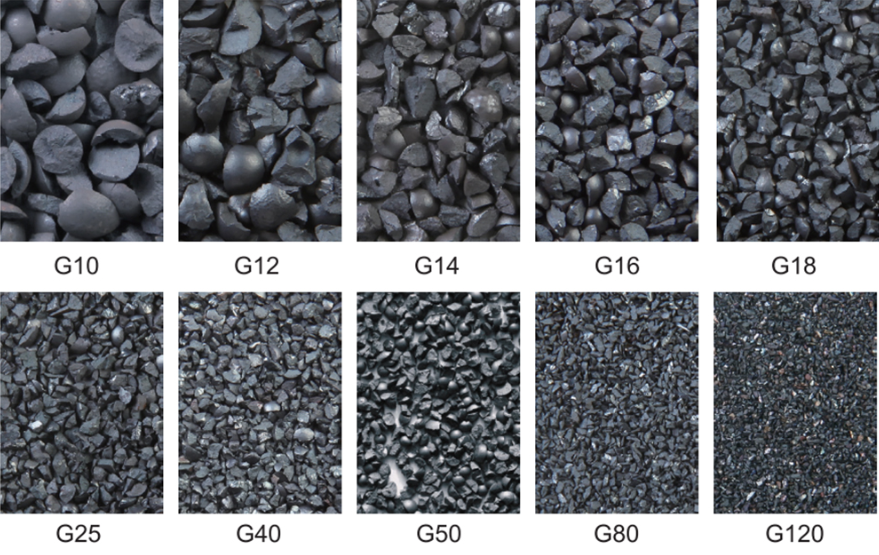

G-10、G-12、G-14、G-16、G-18、G-25、G-40、G-50、G-80、G-120

Steel grit production implementation standards

We strictly comply with the national standard "GB/T18838.3-2008 High Carbon Cast Steel Shots and Sand", American Steel Casting Association "SFSA20-66 Cast Steel Abrasive Standard", American Society of Automotive Engineers "SAE J1993 Cast Steel Sand Standard", People's Republic of China Ferrous metallurgical industry "YB/T5150-1993 Cast Steel Grit Standard", U.S. military standard "MIL-S-851C Metallic Steel Grit and Steel Shots for Cleaning and Strengthening" and International Organization for Standardization "ISO11124-3 High Carbon Cast Steel Shot Casting Steel Grit Standard" to produce.

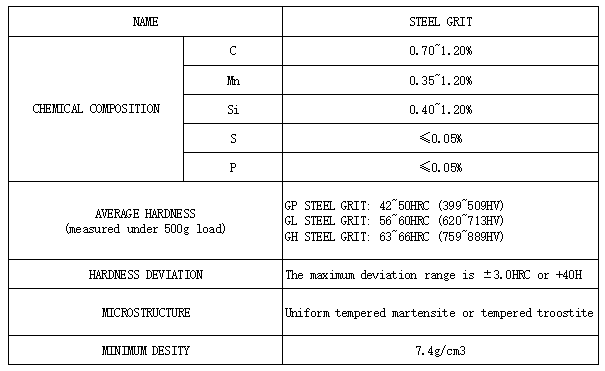

Technical indicators of steel grit

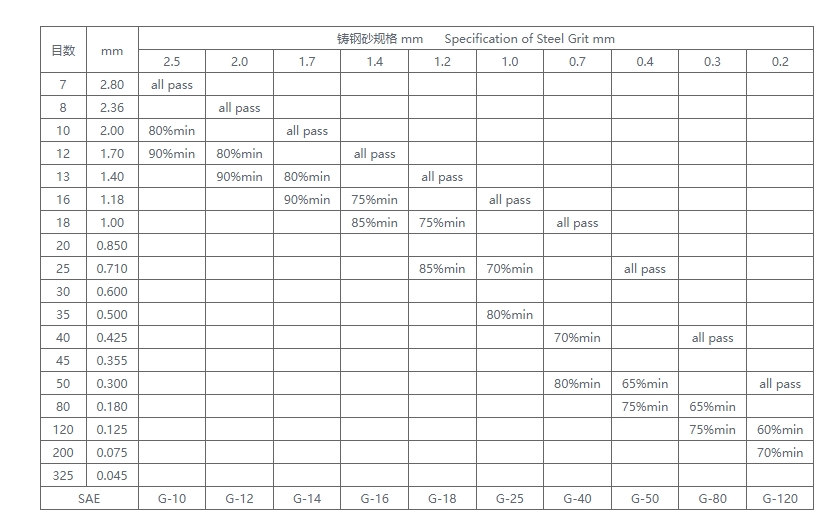

Particle size distribution of steel grit

Steel grit with different hardness

1. GP steel grit: When this kind of abrasive is newly made, it is sharp-edged, and the edges and corners are quickly rounded during use. It is especially suitable for pre-treatment operations of removing oxide scale from the surface of steel.

2. GL steel grit: Although the hardness of this type of steel grit is higher than that of GP steel grit, it will still lose its edges and corners during the sandblasting process. It is especially suitable for pretreatment of steel surface to remove oxide scale.

3. GH steel grit: This type of steel grit has very high hardness and will always maintain edges and corners during sandblasting operations. It is particularly effective in forming regular, hairy surfaces. When GH steel sand is used in shot blasting machine operations, occasions where construction requirements take precedence over price factors (such as roll treatment in cold rolling mills) should be considered. This steel grit is mainly used in compressed air shot peening equipment.

Applicable equipment for steel grit

Steel sand is mainly suitable for sandblasting rooms, mainly for drum-type, chain-type, hook-type, crawler-type, through-type, turntable-type, accumulation-type, step-by-step,

and trolley-type shot blasting machines (shot blasters) , shot blasting machine, shot blasting equipment, shot blasting machine, shot blasting, shot blasting equipment, sandblasting machine,

sandblasting equipment, rust removal equipment, steel pretreatment production line, steel plate pretreatment production line, steel structure pretreatment production line , Equipment in the sand room.

Drum type shot blasting cleaning machine, steel (rubber) crawler type shot blasting cleaning machine, trolley type shot blasting cleaning machine, turntable type shot blasting (reinforced) cl-

eaning machine, hanging chain two-stroke, step-by-step, accumulation cleaning machine, crane Hook-type shot blasting (blasting) cleaning machine, roller-type shot blasting cleaning machine and

steel plate pretreatment line, trolley-type shot blasting (blasting) cleaning machine, cylinder and steel pipe inner and outer wall cleaning machine, leaf spring, round spring, Crankshaft, connecting

rod shot blasting machine, special sanding machine for aluminum alloy, zinc alloy, stainless steel, special double-station squirrel cage cleaning machine for cylinder block (cylinder head),

special cleaning machine for parts in engineering machinery, automobiles, motorcycles and other industries , Marine anchor chain cleaning machine, carbon rod surface cleaning machine,

steel, component cleaning machine, vehicle shot blasting cleaning machine, hook trolley combined shot blasting machine, steel belt shot blasting strengthening machine, chain turntable shot blasting

cleaning machine Machine, steel plate vertical shot blasting machine, mesh belt cleaning machine, disc round shot blasting machine, porcelain tile shot blasting machine, hook swing shot blasting machine

and other equipment.